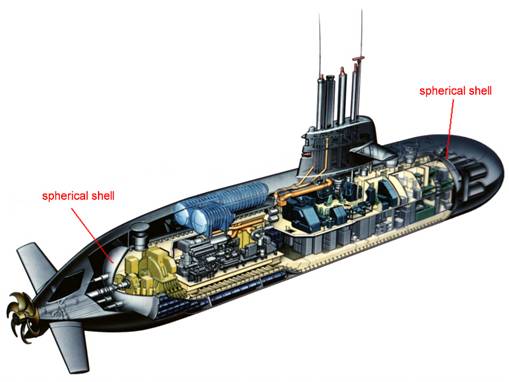

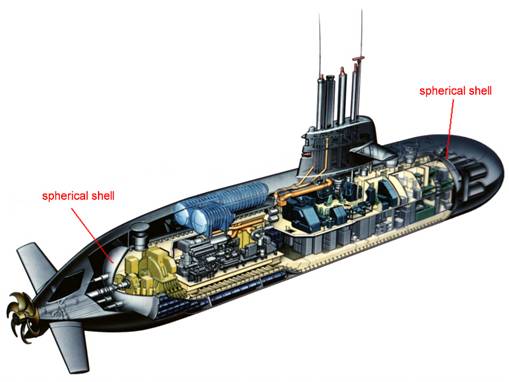

Thick spherical shells made out of HY-80 steel are mainly used in the construction of submarines. They form an essential part of the pressure hull. Spherical shells are constructed by welding preformed shell parts together. Residual stresses are developing in the shell due to the welding process. This project aims to investigate the effect of these stresses on the buckling strength of the shell under external pressure loading.

The influence of residual stress on the stability of the shell structure will be investigated using numerical methods. Precise input data of the residual stress field is needed for the analysis.

Measurements on full scale weld samples are therefore carried out using Neutrondiffractiontechniques. Destructive techniques are used for comparison.

It is very difficult to calculate the critical buckling pressure using “normal” (implicit) FE-methods, due to numerical instability (negative stiffness matrix) when the structure reaches the critical load. Therefore explicit FE-methods are used, which are mainly used for crash analysis.

A first demonstration problem can be found here.

Lars Grünitz,

M.Sc. (Eng) UCT

Supervisor: Prof. Dr.-Ing.W. Fricke

Supported by: Deutsche Forschungsgemeinschaft

Revised: March 2002